PULLMAN, WA – Ethanol from garbage and other sources could replace fossil fuels in the manufacturing of plastics, rubber, and other chemicals if scientists can gain the needed knowledge of catalysis.

WSU Professors Yong Wang and Junming Sun are conducting research and have developed a one-step process for upgrading ethanol to isobutene, an important first step in turning bio-ethanol into other useful, petroleum-based products.

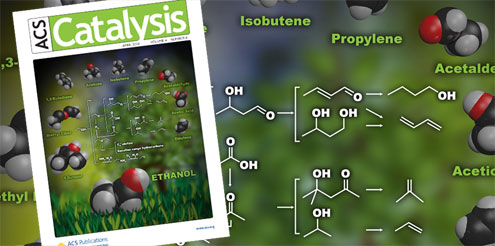

In an article which recently appeared in the journal ACS Catalysis, the researchers provided an overview of work to convert ethanol to valuable chemicals and identified future research directions, including one-step ethanol conversions. Wang is the Voiland Distinguished Professor in the Voiland School of Chemical Engineering and Bioengineering as well as associate director at the Institute for Integrated Catalysis at Pacific Northwest National Laboratory. Sun is a research professor at WSU.

Renewable fuel requirements are increasing the availability and decreasing the cost of ethanol, with the production in the United States expected to reach more than 30 billion gallons in 2017.

With only 15 to 16 billion gallons needed for fuel blending, the additional alcohol could be used to produce plastic water bottles, carpet backing, and thousands of other products. Wang and Sun’s study provided a detailed summary of the research, giving scientists a needed overview.

“We need to de-bottleneck the process, from lignocellulose to the end products,” said Wang.

In the article, the team reviewed the progress made on deconstructing ethanol to provide hydrogen for use in proton exchange membrane fuel cells. Ethanol is of interest because of its easy-to-use form, nontoxicity, and high hydrogen content. Highly stable and selective catalysts, based on cobalt and other earth-abundant metals, appear promising for hydrogen production. Yet, efficiency and deactivation issues remain.

The team also discussed the production of light olefins, which can be used for building alkenes, alkanes, and aromatics, which are longer chained or ring-structured hydrocarbons. For example, producing the light olefin using gamma aluminum oxide is a commercial success. However, the reaction requires high temperatures when water is present. Questions remain, including the formatting of key intermediates, which inhibit the effective conversion of ethanol.

“Olefins are exciting because they are a nice platform molecule that can be further converted to other chemicals,” said Wang. “Essentially, the potential is great, but if you look at the current status, a significant amount of research is needed before commercialization.”

The researchers are continuing to better understand the catalysts and the reaction mechanisms involved, including the influence of impurities introduced with the bioethanol. They are also looking at the coupling thermochemical conversions to biological processes that produce the ethanol.